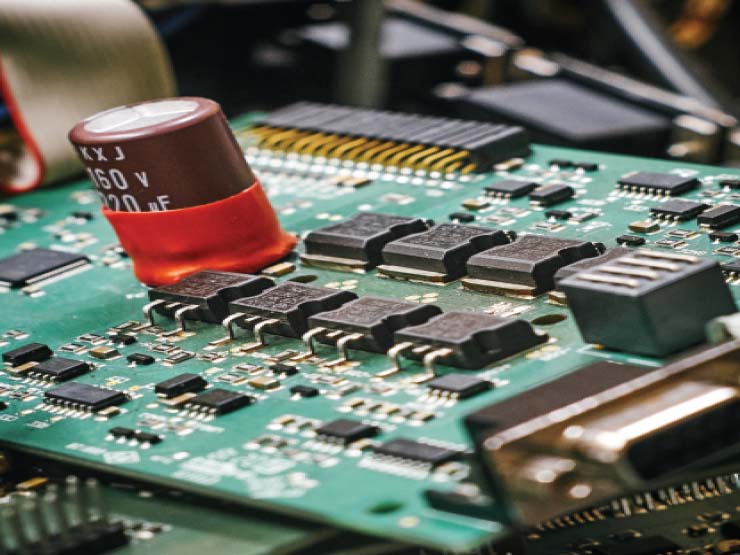

Firstseal , a leading Electronics Adhesive Manufacturer in Gujarat, delivers high-performance bonding, insulation, and protection for a wide range of electronic applications. Our products, including PTFE tapes, masking tapes, duct tapes, aluminum foil tapes, and specialty sealants, are engineered to meet the demanding standards of the electronics industry. They provide strong adhesion, effective insulation, and long-lasting durability for applications such as PCB assembly, wire harnessing, component mounting, and EMI/RFI shielding. Trusted by electronics professionals across Gujarat and India, Firstseal adhesives help optimize production processes, enhance safety, and achieve superior quality in every project. Explore our range to find the perfect solution for your electronics applications.

We Provide Quality Products for Electronics Industry.

In the electronics industry, masking tape withstands high temperatures for soldering, VHB tape mounts displays and panels securely, and double-sided foam tape secures components, providing cushioning and vibration damping.

The electronics industry encompasses the design, development, and production of electronic components and devices, including consumer electronics like smartphones, laptops, televisions, and wearables, as well as industrial and automotive electronics, medical devices, and communication equipment. This industry is integral to global innovation, with advancements in technology constantly pushing the boundaries of what’s possible.

Other Industries

Frequently Asked Questions

1. What adhesive tapes does Firstseal provide for the electronics industry?

Firstseal offers a range of specialized tapes for electronics manufacturing, including heat-resistant masking tapes, precision double-sided foam tapes, anti-static tapes, and VHB tapes for mounting displays and panels securely.

2. How do Firstseal tapes support electronics assembly and production?

Our tapes provide strong adhesion, cushioning, vibration damping, and insulation, ensuring the protection and secure placement of delicate electronic components during manufacturing and use.

3. Are Firstseal tapes suitable for high-temperature electronics processes like soldering?

Yes, Firstseal masking tapes are engineered to withstand high temperatures typically encountered in soldering and other electronics assembly processes without residue or damage.

4. Can Firstseal tapes be used in consumer electronics as well as industrial electronics?

Absolutely. Firstseal supplies tapes suitable for a wide range of electronics, from consumer devices like smartphones and laptops to industrial and automotive electronics, medical devices, and communication equipment.

5. How does Firstseal ensure quality and reliability in its electronics tapes?

Manufactured with high-precision processes, Firstseal tapes undergo strict quality control to ensure consistent performance, durability, anti-static properties, and compliance with electronics industry standards.